If you like reading this blog, be sure to check out our Plastic Packaging Blog, featuring new content from all over the world!

Get the Latest Industry News Delivered to your Inbox Each Month

|

|

Thank you for Signing Up |

March 1, 2020

Minnesota Town Replaces Storm Sewer Pipe with PVC Pipe

Minnesota Town Replaces Storm Sewer Pipe with PVC Pipe

Wayzata, MN recently had a 50-to-60-foot section of a storm sewer pipe deteriorate forcing the town to replace that section. The deterioration ended up causing erosion to the hill it ran under because it had been there since the 1940’s. City Director of Public Works, Mike Kelly stated, “There wasn’t much pipe left. It literally was an old metal pipe that had rotted out, so we went in and removed the old pipe and replaced it with a new PVC plastic pipe, we hope it’ll last forever.” The cost of the projects totaled between $10,000 to $12,000. The project was small scale but very necessary to keep the sanitary maintenance of the city up to par.

The town also decided the rest of the piping in the city should be lined with cured-in-place pipe liner so no similar issues come up in the future. “It’s very unobtrusive. We’re lining sewer pipes that are already in the ground, so we’re not digging anything up, what it does is it provides an interior liner to some of our old pipes that give it a little bit more strength. And those liners can last 75 years” Kelly says.

The town also decided the rest of the piping in the city should be lined with cured-in-place pipe liner so no similar issues come up in the future. “It’s very unobtrusive. We’re lining sewer pipes that are already in the ground, so we’re not digging anything up, what it does is it provides an interior liner to some of our old pipes that give it a little bit more strength. And those liners can last 75 years” Kelly says.

March 2, 2020

CarbonLite Investing in Bottle-to-Bottle Recycled PET Plant

CarbonLite Investing in Bottle-to-Bottle Recycled PET Plant

Recycled content plastic from beverage companies has been increasing in demand so CarbonLite industries have decided to act on it. Chairman, Leon Farahnik says, "We are doing this because of our customer base and the need for the post-consumer content in their product line, we supply all the major beverage companies across the country with post-consumer content." They are one of the largest makers of food-grade post-consumer PET resin and are investing $80 million in a facility near Orlando that would have the capacity to hold 220 million pounds of PET resin from their existing three plants and an additional 300 million pounds with the Florida plant.

Many large beverage companies like Nestle Waters, Niagara Bottling LLC, Coca Cola Co., and Keurig have announced that they want to make commitments to incorporating recycled content PET into their bottles. These companies are very large and work at an enormous scale so the amount of recycled PET would be substantial. Hopefully, CarbonLite will inspire other producers of food-grade recycled PET resin to invest in more facilities to up their production. Recycled material has become a huge selling point for large companies and will only continue to grow.

Read more about CarbonLite and their recycled PET production here.

Many large beverage companies like Nestle Waters, Niagara Bottling LLC, Coca Cola Co., and Keurig have announced that they want to make commitments to incorporating recycled content PET into their bottles. These companies are very large and work at an enormous scale so the amount of recycled PET would be substantial. Hopefully, CarbonLite will inspire other producers of food-grade recycled PET resin to invest in more facilities to up their production. Recycled material has become a huge selling point for large companies and will only continue to grow.

Read more about CarbonLite and their recycled PET production here.

March 3, 2020

US Army is Utilizing 3D Printing of Recycled Plastic

US Army is Utilizing 3D Printing of Recycled Plastic

The US Army Research Laboratory and the US Marine Corps have been collaborating to discover how they can utilize waste plastics for soldiers on the battlefield. By using water bottles, milk jugs and yogurt containers plastics they can 3d print important parts for military supplies. Two members of the U.S. Marine Corps have researched and developed filament from 100% recycled polyethylene terephthalate (PET) from bottles and plastics without any chemical modifications or additives. The filament can then be used in 3d printers and replace off the shelf PET pellets that they currently use.

The US and coalition forces produce large amounts of plastic waste and repurposing this waste would have several benefits. It would improve the self-reliance of service members on forward operating bases, cut costs and reduce demand for the resupply of parts. If they can repurpose the plastic on location they will also reduce the logistics burden of transporting parts forward to other operating bases and reduce the cost of disposing of recyclable material. Research still needs to be done but they are well on their way to utilizing recycled plastic efficiently and effectively within military forces.

To read more about what the Army and Marine Corps have been doing with recycled plastics click here.

The US and coalition forces produce large amounts of plastic waste and repurposing this waste would have several benefits. It would improve the self-reliance of service members on forward operating bases, cut costs and reduce demand for the resupply of parts. If they can repurpose the plastic on location they will also reduce the logistics burden of transporting parts forward to other operating bases and reduce the cost of disposing of recyclable material. Research still needs to be done but they are well on their way to utilizing recycled plastic efficiently and effectively within military forces.

To read more about what the Army and Marine Corps have been doing with recycled plastics click here.

March 4, 2020

Two Major International Plastics Events Have Been Postponed Due to Coronavirus

Two Major International Plastics Events Have Been Postponed Due to Coronavirus

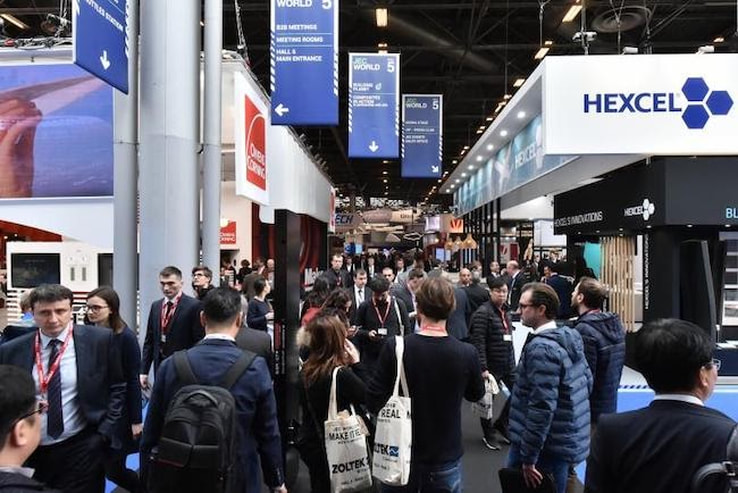

At the beginning of February the largest plastics exhibition in the world, Chinaplas was postponed due to coronavirus fears. A statement by the organizers of Chinaplas, Adsale Exhibition Services states, “In order to control the novel coronavirus epidemic in China, and in accordance with the instructions issued by the Shanghai city government to stop all large-scale activities, please be informed that Chinaplas 2020, the 34th International Exhibition of Plastics and Rubber Industries, scheduled to be held on 21st to 24th April at National Exhibition and Convention Center in Shanghai will be postponed. New dates for the show will be announced at a later time.” In addition to this, the JEC World Composites Exhibition has been postponed until May because of the coronavirus as well. The event is held in Paris and is the leading tradeshow of the composites industry. That makes two major events within the industry that needed to be postponed because of the epidemic. To get more information on the events click here for JEC World Composites Exhibition and here for Chinaplas.

© Copyright Bryan Hauger Consulting, Inc., 2018. All rights reserved.