Get the Latest Industry News Delivered to your Inbox Each Month

|

|

Thank you for Signing Up |

May 1, 2020

What is Heat Fusion Joining?

What is Heat Fusion Joining?

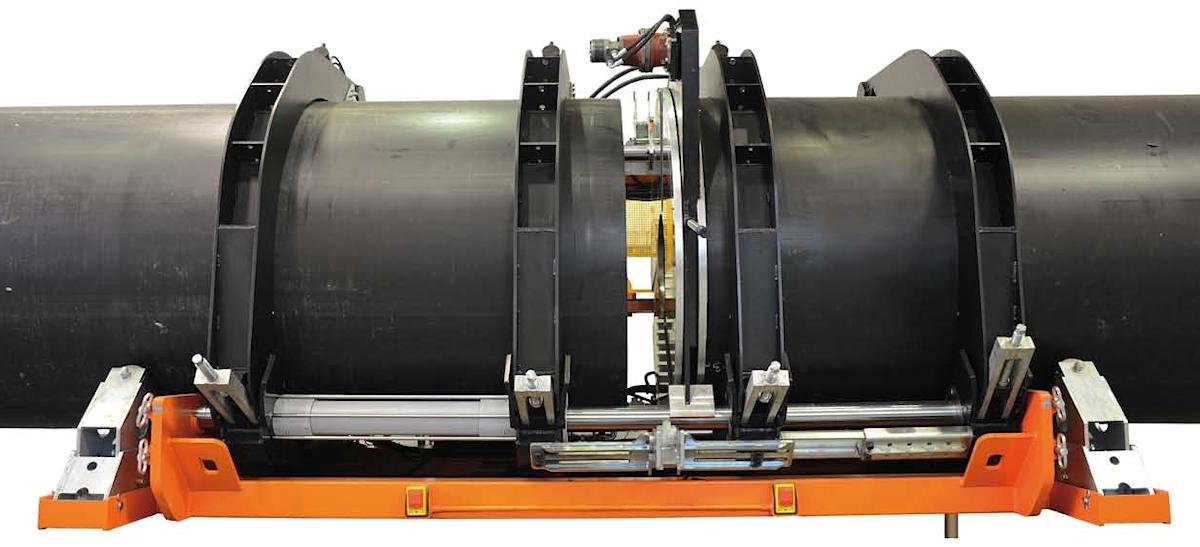

Within the plastic pipe industry, the joining of two plastic pipes - like the HDPE pipes shown above - through heating and welding two components is a common practice. Sometimes called pipe coupling or heat fusion joining, but it is most commonly referred to as butt fusion. At its most simplistic level, heat is applied by an electrical heating plate to the ends of both parts simultaneously until melting occurs. Then, the heater plate is removed and pressure is applied for a specified period of time creating "weld beads”. The joint has a typical appearance when properly constructed which is used in joint inspections or audits - especially for critical applications like natural gas pipe.

While this process seems pretty straightforward there are many variables that can affect the quality of the fusion joint. These are called essential variables and they must be controlled within an acceptable range to provide reasonable assurance of strong and durable joints. These variables and many more need to be completely controlled in order for the fusion process to be successful, efficient, and most of all, safe. Read more about Butt fusion on our website by clicking this link, You can also read more about the variables that affect butt fusion here.

While this process seems pretty straightforward there are many variables that can affect the quality of the fusion joint. These are called essential variables and they must be controlled within an acceptable range to provide reasonable assurance of strong and durable joints. These variables and many more need to be completely controlled in order for the fusion process to be successful, efficient, and most of all, safe. Read more about Butt fusion on our website by clicking this link, You can also read more about the variables that affect butt fusion here.

May 2, 2020

SRM University Professor is Developing Face Shields for Frontline Workers

SRM University Professor is Developing Face Shields for Frontline Workers

Dr. Panchagunula Jayaprakash is an assistant professor at SRM University and has a PhD in additive manufacturing. His passion has led him to the realm of 3d printing where he has begun to develop face shields for frontline workers. He tested multiple designs based on different factors like length and how far from the face they were. He also decided to test a few of his prototypes with frontline workers like the police force and some doctors so he could use their feedback to perfect his mask. Getting feedback from people who are actually going to use it is a commendable idea, Jayaprakash says, “In fact, it was my wife who proposed that I should take feedback from people who are really going to use it.” The mask is fitted with a band and 100-micron thickness that keeps anything from entering the eyes, nose, or mouth.

In addition to this project, Dr. Jayaprakash is a professor and he teaches Manufacturing Science, Additive Technology Processes, and Additive Manufacturing. Based on the feedback that he receives; he hopes to zero in on one of his designs depending on the feedback and then go into mass production. He would then need government approval to distribute the face shields. It is good to see someone with the passion and skills to do something like this in a highly beneficial way during this pandemic.

Read more about this developing face mask here.

In addition to this project, Dr. Jayaprakash is a professor and he teaches Manufacturing Science, Additive Technology Processes, and Additive Manufacturing. Based on the feedback that he receives; he hopes to zero in on one of his designs depending on the feedback and then go into mass production. He would then need government approval to distribute the face shields. It is good to see someone with the passion and skills to do something like this in a highly beneficial way during this pandemic.

Read more about this developing face mask here.

May 3, 2020

PepsiCo, L'Oreal, and Nestle are Backing a French Plastics Recycling Startup

PepsiCo, L'Oreal, and Nestle are Backing a French Plastics Recycling Startup

The new French startup called Carbios is trying to change how companies recycle plastic and hopefully change the plastic industry as a whole. Normally, plastic recycling technology reuses plastic by melting it down and reforming it into new products. This process can weaken the plastic and cause impurities in the material. So overall, plastic isn’t really recycled but it’s down-cycled. Chief Scientific Officer at Carbios, Alain Marty says, "It’s not even recycling. It’s more a possibility to reuse plastics a few times. After a few cycles, it’s not possible to reuse this polymer, and it’s incinerated or goes to a landfill. The Carbios systems can take all plastic; colored PET, textiles like polyester, or even carpet, which would normally be lost along the way. They can take it in and recover it.”

Carbios’ groundbreaking technology has massive potential and it has received backing by some of the largest consumer product companies in the world. PepsiCo, L’Oreal, and Nestle are all backing the startup with large investments. PET plants normally just use thermo-mechanical technology, but if Carbios’ enzyme technology were to be adopted, recycling could completely change the consumer product market. These large companies have been leveraging their long-standing relationship with PET plants to help Carbios get their foot in the door. If such massive companies like PepsiCo, L’Oreal, and Nestle are willing to help this small company then it must have some promise. Hopefully, the industry takes notice and helps Carbios change the way the world recycles.

Read more about Carbios and how they are changing recycling here.

Carbios’ groundbreaking technology has massive potential and it has received backing by some of the largest consumer product companies in the world. PepsiCo, L’Oreal, and Nestle are all backing the startup with large investments. PET plants normally just use thermo-mechanical technology, but if Carbios’ enzyme technology were to be adopted, recycling could completely change the consumer product market. These large companies have been leveraging their long-standing relationship with PET plants to help Carbios get their foot in the door. If such massive companies like PepsiCo, L’Oreal, and Nestle are willing to help this small company then it must have some promise. Hopefully, the industry takes notice and helps Carbios change the way the world recycles.

Read more about Carbios and how they are changing recycling here.

© Copyright Bryan Hauger Consulting, Inc., 2018. All rights reserved.