If you like reading this blog, be sure to check out our Extrusion Blog, featuring new content.

Get the Latest Industry News Delivered to your Inbox Each Month

|

|

Thank you for Signing Up |

November 1, 2020

BHC Consultant Nathanial Evans Selected as ASTM International Emerging Professional

BHC Consultant Nathanial Evans Selected as ASTM International Emerging Professional

Bryan Hauger Consulting (BHC) is proud to announce that Nathanial Evans, director of testing services, has been selected as an ASTM International Emerging Professional for 2020. The program allows candidates with demonstrated potential in their industry to become more active on the committee which nominated them, furthering professional development and leading to new opportunities. Each candidate is required to have one to five years of experience working with ASTM standards, either through development of the standards or in using them in their work. Emerging Professionals receive invitations to professional workshops and training while also participating in the technical committee which nominated them.

When asked about being selected for the ASTM International Emerging Professionals Program, Nathanial said, “I am honored to have been nominated and selected as an ASTM International Emerging Professional for 2020. I want to thank ASTM for selecting me, and I especially want to thank Dr. Bryan Hauger for nominating me. This means a great deal to me both professionally and personally. I am looking forward to participating in the EP program this year and am happy to be participating in the new virtual EP workshop that ASTM just recently rolled out for the first time in June of this year. I have been working with ASTM testing and product standards since my undergraduate days in college. I am excited to learn more about the organization and how it works as an EP in ASTM's 2020 Emerging Professional Program.” Congratulations, Nathanial!

When asked about being selected for the ASTM International Emerging Professionals Program, Nathanial said, “I am honored to have been nominated and selected as an ASTM International Emerging Professional for 2020. I want to thank ASTM for selecting me, and I especially want to thank Dr. Bryan Hauger for nominating me. This means a great deal to me both professionally and personally. I am looking forward to participating in the EP program this year and am happy to be participating in the new virtual EP workshop that ASTM just recently rolled out for the first time in June of this year. I have been working with ASTM testing and product standards since my undergraduate days in college. I am excited to learn more about the organization and how it works as an EP in ASTM's 2020 Emerging Professional Program.” Congratulations, Nathanial!

November 2, 2020

Megapipes' Weholite HDPE Pipes Help Solve Kenya’s Sanitation Problems

Megapipes' Weholite HDPE Pipes Help Solve Kenya’s Sanitation Problems

Kenya has been struggling to bring proper sanitation and storm water management to many areas of the country despite the objectives of its Millennium Development Goal. Currently, only 30% of Kenyans have access to improved sanitation. It is a challenge not only in rural areas but also in urban areas where growth is outpacing the provision of basic services such as sanitation. Megapipes Solutions is a new Kenyan company providing large diameter Weholite pipes to help meet these sanitation needs.

Weholite is a high density polyethylene (HDPE) pipe that is lightweight and has an engineered, structured wall perfect for low pressure and gravity applications like for sewage and storm water. The Weholite pipe is durable and abrasion resistant with lifetimes expected over 100 years. Megapipes Solutions is currently constructing a factory to manufacture these pipes in Ruiru in Kiambu county and will serve all of Kenya in addition to neighboring countries.

Weholite is a high density polyethylene (HDPE) pipe that is lightweight and has an engineered, structured wall perfect for low pressure and gravity applications like for sewage and storm water. The Weholite pipe is durable and abrasion resistant with lifetimes expected over 100 years. Megapipes Solutions is currently constructing a factory to manufacture these pipes in Ruiru in Kiambu county and will serve all of Kenya in addition to neighboring countries.

November 3, 2020

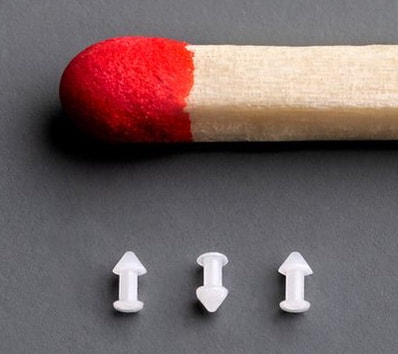

ENGEL Introduces New Micro-Injection Unit for Liquid Silicone Rubber

ENGEL Introduces New Micro-Injection Unit for Liquid Silicone Rubber

ENGEL recently announced the launch of a new liquid silicone rubber (LSR) micro-injection unit capable of the lowest shot weights available. The unit is an all-electric e-motion 50/30 TL injection molding machine and is currently being used in combination with an LSR metering pump by ACH Solution to produce ophthalmic diagnostic equipment components weighing just 0.0013 grams and measuring less than 1.7 mm in length. An ENGEL viper 6 linear robot is used to remove the microparts and place them on a conveyor belt where an ACH Solution camera system is then used for quality control.

The new e-motion TL molding machine is highly flexible with a quick coupling system allowing a conventional screw injection unit to replace the micro-injection unit in less than 30 minutes. With no tie bars being used, the platens can be used all the way to the edge, reducing the system footprint and unit costs. This new system has uses in the automotive, medical technology and consumer electronics industries.

To read more about the new ENGEL e-motion TL injection molding machine, click here.

The new e-motion TL molding machine is highly flexible with a quick coupling system allowing a conventional screw injection unit to replace the micro-injection unit in less than 30 minutes. With no tie bars being used, the platens can be used all the way to the edge, reducing the system footprint and unit costs. This new system has uses in the automotive, medical technology and consumer electronics industries.

To read more about the new ENGEL e-motion TL injection molding machine, click here.

November 4, 2020

Pyrometers Are Key for High-Quality Thermoplastics Heating

Pyrometers Are Key for High-Quality Thermoplastics Heating

Continuous fiber-reinforced thermoplastics, often used in automotive engineering, offer extreme strength while also being lightweight. They also have good mechanical properties and can be used in complex geometries. Injection molding allows manufacturers to create the shape they need in the material they want while also incorporating metal parts at the same time. KraussMaffei has developed a new technique for producing these large-format parts to a high standard using continuous fiber-reinforced thermoplastic semi-finished products, called organo sheets.

Organo sheets are formed using carbon, glass, aramid, or composite fiber layers embedded in a thermoplastic matrix such as polypropylene or polyamide. The sheets are then heated before thermoforming them into the desired shape and then back-injection molding them. The heating of the organo sheets is critical for a successful process, however. KraussMaffei’s new infrared heating technology uses pyrometers from Optris along with intelligent control software technology for a complete hardware and software integrated system that is capable of uniform, rapid heating of the sheets that was not previously possible. The system is connected to injection molding machines via a standard Europmap 18 interface and can be retrofitted to current injection molding machines. To read more about KraussMaffei’s new technology, click here.

Organo sheets are formed using carbon, glass, aramid, or composite fiber layers embedded in a thermoplastic matrix such as polypropylene or polyamide. The sheets are then heated before thermoforming them into the desired shape and then back-injection molding them. The heating of the organo sheets is critical for a successful process, however. KraussMaffei’s new infrared heating technology uses pyrometers from Optris along with intelligent control software technology for a complete hardware and software integrated system that is capable of uniform, rapid heating of the sheets that was not previously possible. The system is connected to injection molding machines via a standard Europmap 18 interface and can be retrofitted to current injection molding machines. To read more about KraussMaffei’s new technology, click here.

November 5, 2020

Global Resources' New $9.5 Million Medical Manufacturing Facility

Global Resources' New $9.5 Million Medical Manufacturing Facility

Global Resources International is investing $9.5 million to open a new medical manufacturing company, Advanced Product Solutions, in Dothan, AL. The new facility will create 70 jobs to manufacture engineered fabrics, personal protective equipment, and injection molded medical devices with plans to expand their products in the future to include non-medical product injection molding as well as absorbent under pads for humans and animals. Eastern Technologies Inc., a long-time GRI subsidiary, will provide operational oversight for Advanced Product Solutions.

To read more about the new plant, click here.

To read more about the new plant, click here.

© Copyright Bryan Hauger Consulting, Inc., 2018. All rights reserved.