Dr. Bryan Hauger's Presentations

|

Hauger, B. E.; Interviewed by Peter Dyke, PE Pipe Alliance – Leader’s Panel; Tulsa, OK; December 2020.

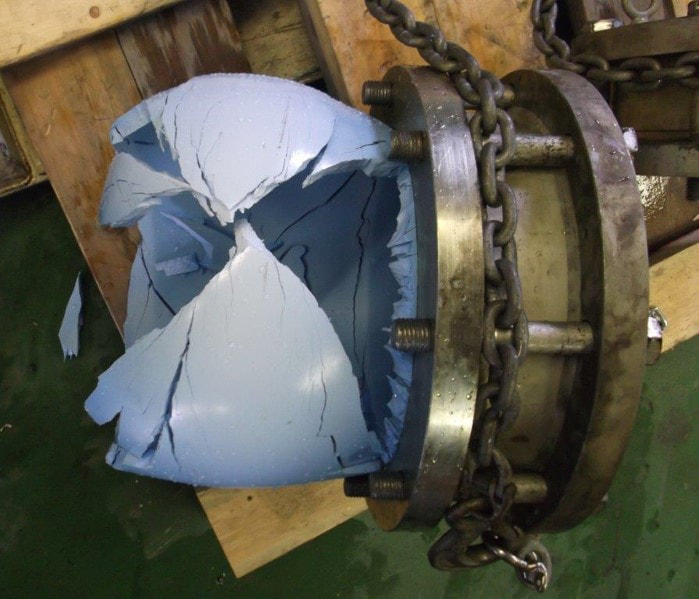

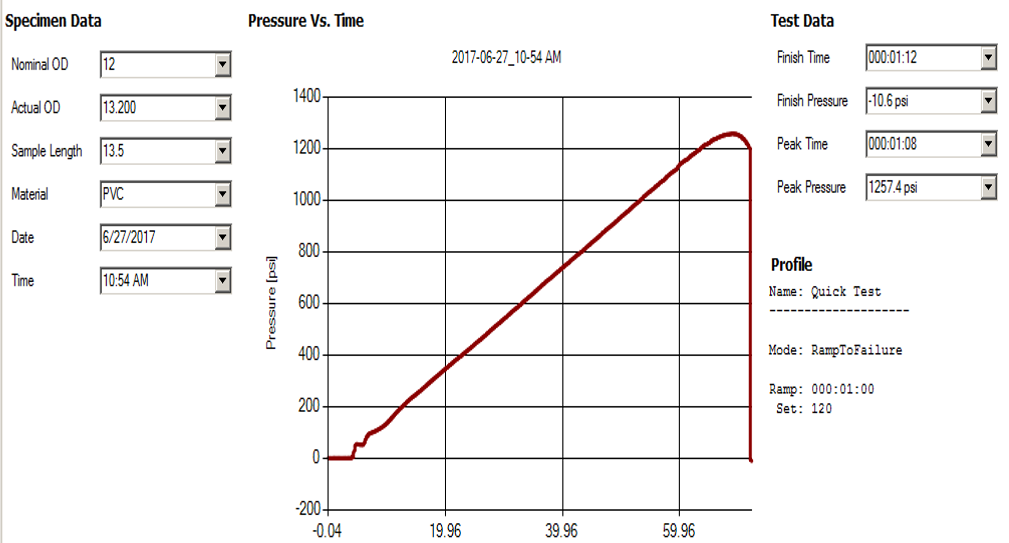

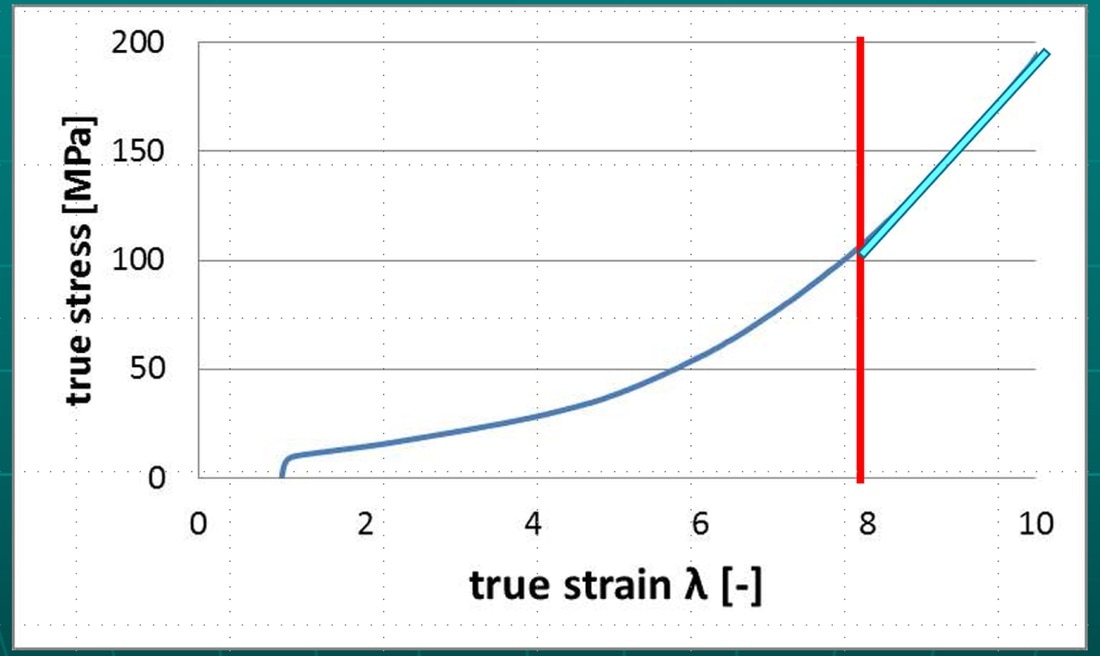

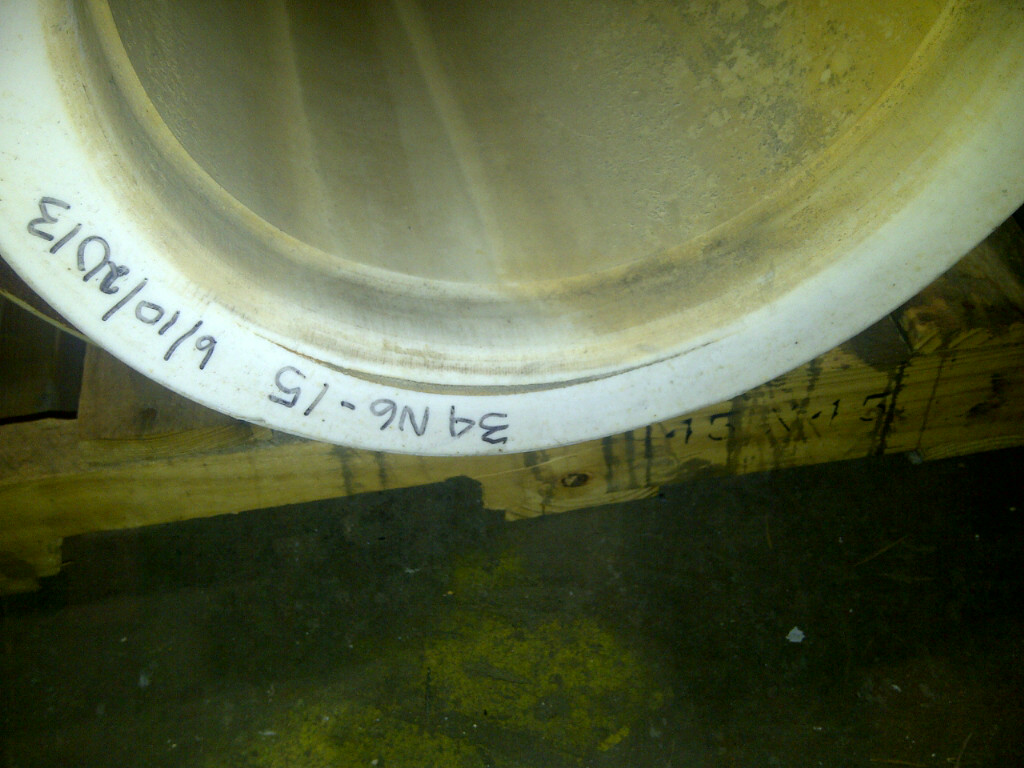

Hauger, B. E.; Failure Analysis of Engineering Thermoplastics, Energy Polymer Group; Houston, TX; August 2020. Hauger, B. E.; Heat Fusion Joining Procedure Qualification for Natural Gas Utilities with PE Distribution Systems, SPE - Plastic Pipe in Infrastructure and Industrial Applications; West Conshohocken, PA; April 2019. Hauger, B. E.; Market Development Opportunities for Recycled Content in Plastic Pipe, 2019 Southeast Recycling Conference; Orlando, Florida; February 24 - 26, 2019. Abstract - Recycled content plays an important and growing role in HDPE corrugated pipe markets. The history of technical advances and standards development for corrugated HDPE pipe provides an important template for plastic piping market development. Hauger, B. E., Hensel, F. W.; Investigations of Sample Length on Plastic Pipe Quick Burst Pressure Test Results. 2017 AMI Conference on Polymer Testing & Analysis USA; Pittsburgh, Pennsylvania; September 19, 2017. Abstract - Quick burst testing by ASTM D1599 is a common test method used by manufacturers of plastic pipe for various plastic materials. This test method includes requirements on the length between end closures relating to pipe nominal outside diameter (OD). For pipe of 6 inch nominal OD or less, samples require a length between end closures not less than 500% of the OD. But for larger sizes, the minimum length between end closures is reduced to 300% of the OD provided this value is not less than 30 inches. We will present our results on PVC piping of 12 inch nominal OD at various sample lengths to determine the effect, if any, of length between end caps on quick burst pressure. Hauger, B. E.; New Developments in Strain Hardening Modulus for Polyethylene Pressure Piping Applications. 2017 SPE International Polyolefin Conference; Houston, Texas; February 28, 2017. Abstract - Strain Hardening Modulus (SHM) is of increasing international interest for its capability to provide a useful index of the slow-crack growth (SCG) performance of polyethylene (PE) materials. Recently, a broad industry initiative has started to formalize an ASTM International test method to measure SHM. This effort likely is driven by several benefits to industry including the significant reduction in time required for SHM measurement in comparison to traditional SCG test methods. This paper will update the literature establishing the capabilities of SHM to replace traditional SCG test methods and provide a progress report in creating a North American standard for this useful test. Hauger, B.E.; Strain Hardening Modulus and Natural Draw Ratio for Polyethylene Pressure Piping Applications. 2016 SPE International Polyolefin Conference; Houston, Texas; February 23, 2016. Abstract - Strain Hardening Modulus (SHM) and Natural Draw Ratio (NDR) have both been widely discussed for their capabilities to provide insights into the slow-crack growth (SCG) performance of polyethylene (PE) materials. At this point, no broad industry initiatives have arisen to formalize an ASTM International procedure for measuring either SHM or NDR. Neither has there been any plastic pipe industry initiatives to introduce either measure into either codes or standards as a replacement or equivalent to existing SCG test methods for PE. Because of the potential benefits to industry from the significant reduction in cost associated with either SHM or NDR in comparison to traditional SCG test methods, it is unfortunate. This paper will present the literature establishing the capabilities of SHM or NDR to replace traditional SCG test methods, consider the reasons industry has not yet adopted these alternative test methods, and propose a path to realization of the potential value of SHM and NDR for PE pressure piping applications. Click Here for 2016 Conference Website Link Click Here for Google+ Link to Paper Hauger, B. E.; SPOOLABLE COMPOSITE PIPE – Part II. Plastic Materials Committee - American Gas Association Conference; Amelia Island, FL; September 30, 2015. Abstract - A presentation considering three subjects of interest was made to the committee; 1) the diversity of spoolable composite materials 2) the spool lengths available and 3) smart sensing technologies for spoolable composite pipe. The types of materials used to reinforce this type of composite pipe was discussed. The spool lengths available in different pressure classes and nominal pipe sizes was featured for North American Manufacturers. Finally, distributed optical fiber sensing technology was examined. Many spoolable composite pipes are available in lengths, sizes and pressure classes such that replacement or rehabilitation of deteriorating metallic pipe without in-line couplings is practical. Hauger, B. E.; State of the Art in Heat Fusion Joining of PE. Accel Fusion - Headquarters; Odessa, Texas. July 23, 2015. Abstract – The presentation was focused on the past and present of butt fusion joining of PE pipe. Without going into procedural details, broad topics were explored including regulatory oversight, testing, qualification, and inspection. Then the presentation jumps to a near future / distant future set of predictions. The near future is anticipated to bring accelerating growth in water pipe on top of accelerating housing starts, more regulatory oversight with some areas of special interest based on recent events in the gas distribution market resulting in more day qualifications of joiners, more third party inspection including non-destructive examination, and more focus on record captures of fusion process, and more focus on tracking and tracing. In short, many layers of additional complexity for in all aspects of joining operations across all market sectors including oil patch are anticipated. Hauger, B. E.; SPOOLABLE COMPOSITE PIPE. Plastic Materials Committee - American Gas Association Conference and Exposition; Grapevine, Texas; May 18, 2015. Abstract - An introductory presentation was made to the sponsoring committee including a generalized discussion of the structure, advantages, and challenges of spoolable composite pipes using polyolefin pipe as the core for gas applications. Installations under special permit or waiver were highlighted along with the plastic and non-metallic materials used in construction of these potentially high-pressure alternatives to metallic piping. Hauger, B. E.; QUALIFICATION TESTING AND LONG-TERM DURABILITY OF PLASTIC-LINED METALLIC PIPE, FITTINGS AND FLANGES FOR CORROSIVE APPLICATION. ANTEC 2015; Orlando, FL; March 23, 2015. Abstract - The potential for successful long-term application of plastic-lined metallic pipe, fittings and flanges in corrosive applications is influenced by a number of factors. One important factor is qualification testing that addresses high-temperature, low-temperature, thermal cycling and vacuum performance. Recently, clarification of the circumstances which lead to re-qualification testing has been balloted to an ASTM standard specification for such plastic-lined composite materials. This paper will document field failures which were potentially avoidable through appropriate qualification (or re-qualification) testing specifically related to dimensional measurements, liner ductility/strength and vacuum testing. Hauger, B.E.; Recent Trends in Polyolefin Pipe Technology and Markets. 2015 SPE International Polyolefin Conference; Houston, Texas; February 24, 2015. Abstract - Polyolefin piping standards maintained at ASTM Committee F17 create a permanent record of industry innovation that is highly market specific and the date of initial publication is recorded. This paper examines several specific examples of technology innovation and market interest that underscore high industry interest and may document high volume growth, high margins, or periods of rapid market rotation. Heavy industry interest in hydraulic fracturing has been reflected in the recent formation of a new subcommittee, ASTM F17.68 on energy piping systems, that includes a variety of new composite piping technology. Recent standards have underlined innovative polypropylene (PP) structural pipes that have recently been accepted for use in the sanitary sewer market. A variety of polyolefin materials rated for water service above 140⁰F are rapidly replacing copper tubing as supported by a wide array of standards for polymer pipe, fittings, and systems. This paper will consider these examples as a means of illustrating the process through which industry investment in technology trends are formalized as new industry standard practice. Hauger, B. E.; Review of Permeation of Hydrocarbons through Plastic Piping Systems. 2013 SPE International Polyolefins Conference; Houston, Texas; February 2013. Abstract - The potential for contamination of potable water by the aromatic components of gasoline, namely benzene, toluene, ethylbenzene, and xylenes (BTEX), is of enduring concern due to their well-known health effects. Permeation of BTEX through plastic pipe and the elastomeric gaskets used in the assembly of some pipe systems has been discussed and debated in academic literature for years. Recently, new insights have been gained through studies of water piping systems by using Fick’s Law and relevant engineering variables. This paper will review the state-of-the-art information regarding the important question of how various water systems may be affected by hydrocarbon permeation. Hauger, B. E.; Basic Properties of HDPE, Material Classification. Seminar on HDPE Piping in Nuclear Power Plants; Charlotte, NC.; June 2011. Hauger, B. E.; "Designing and Installing Corrugated High-Density Polyethylene for Drainage Applications" Program for Registrants to the CPPA Division of Plastic Pipe Institute December 2005. |

© Copyright Bryan Hauger Consulting, Inc., 2014 - 2021. All rights reserved.